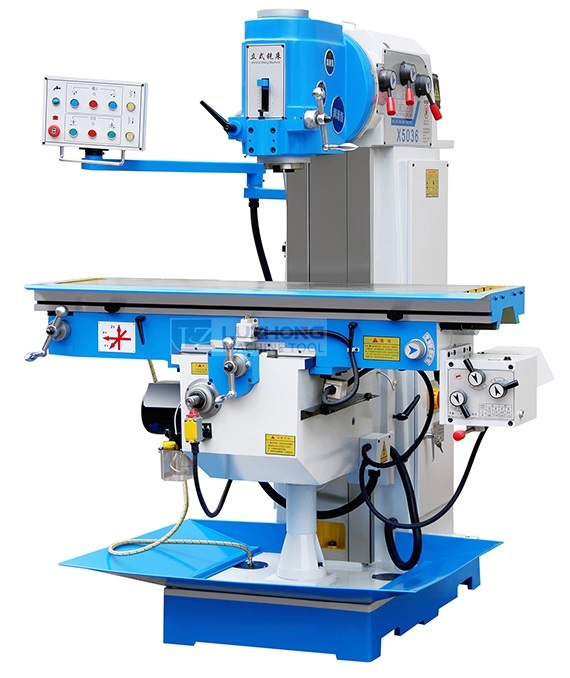

Vertical knee type milling machine

Vertical knee type milling machine Specification

- Product Type

- Vertical knee type milling machine

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 415 Volt (v)

- Weight (kg)

- 2500 Kilograms (kg)

- Dimension (L*W*H)

- 2000x1800x1800 Millimeter (mm)

- Color

- Green

- Warranty

- 1 Year

Vertical knee type milling machine Trade Information

- Minimum Order Quantity

- 1 Number

- Main Domestic Market

- All India

About Vertical knee type milling machine

Vertical knee type milling machineMilling Machine

Universal knee type milling machine

horizontal milling machine

vertical milling machine

DRO Milling Machine

Dividing head

HV rotary table

Boring head

drill chuck

Advanced Automation and Precision Control

Equipped with a Human Machine Interface (HMI), this milling machine enables operators to seamlessly manage processes and make adjustments on-the-fly. The automatic control system ensures consistent milling outcomes, reducing the likelihood of errors while maximizing output. Designed for modern facilities, it supports both efficiency and high-precision work.

Robust Build for Industrial Workloads

Engineered with a solid electric drive and weighing 2500 kg, this vertical knee type milling machine stands strong under demanding conditions. Its generous dimensions allow for handling sizable materials, making it ideal for heavy-duty operations in diverse sectors. The green finish signifies durability and professional-grade quality.

FAQs of Vertical knee type milling machine:

Q: How does the Human Machine Interface improve operation efficiency?

A: The Human Machine Interface (HMI) streamlines operations by allowing users to monitor, control, and adjust machine settings easily in real-time, leading to enhanced precision, less downtime, and user-friendly operation.Q: What materials or tasks is the vertical knee type milling machine best suited for?

A: This machine excels in milling and shaping metals and alloys, making it suitable for component fabrication, tooling, and general manufacturing processes where adaptability and accuracy are required.Q: When should routine maintenance be performed on this milling machine?

A: Routine maintenance is generally recommended every 2-3 months, depending on operational intensity, to ensure optimal performance and prolong lifespan. Refer to the manufacturers manual for detailed guidelines.Q: Where can this milling machine be installed?

A: Due to its robust size (2000x1800x1800 mm) and weight (2500 kg), it is best installed in industrial workshops or manufacturing facilities with suitable foundation and sufficient space for safe operation.Q: What is the process for starting up and operating the machine?

A: After securing the machine and connecting it to a 415V power source, operators can use the HMI panel to initialize settings, select desired operations, and start the automatic milling process, ensuring all safety procedures are followed.Q: How does the 1-year warranty benefit users?

A: The 1-year warranty covers manufacturing defects and certain repairs, giving users peace of mind and protection against unexpected technical issues during the initial period of use.Q: What are the key advantages of using this milling machine in a production line?

A: Key benefits include higher productivity thanks to automation, consistent milling precision due to the HMI, and the robust electric drive system which accommodates continuous, large-scale production requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Tools Category

Pentagon SEMI UNIVERSAL Dividing or Indexing Head Set model PBS2

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 40 kg

Color : Other, Machine Grey

Product Type : Semi Universal Dividing or Indexing Head Set

Drive Type : Other, Gear Drive

Pentagon SEMI UNIVERSAL Dividing or Indexing Head Set model PBS0

Price 42000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 14 kg

Color : Green

Product Type : Dividing or Indexing Head Set

Drive Type : Other, Manual drive

SINO BRAND DRO Set along with 3 Axis DRO Display and Linear Scale Resolution 0.005 mm

Price 34900 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Display Unit: Approx. 2.4 kg, Scales: Varies by length

Color : Other, Display: Black; Scales: Silver

Product Type : DRO Set with Linear Scales

Drive Type : Other, Electronic

DELOS BRAND DRO Set along with 2 Axis DRO Display and Linear Scale Resolution 0.005 mm

Price 23400 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx 2.5 kg (Display Unit)

Color : Other, Grey/Black

Product Type : Digital Readout DRO System

Drive Type : Other, Electronic/Manual

|

PENTAGON MACHINES AND TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |