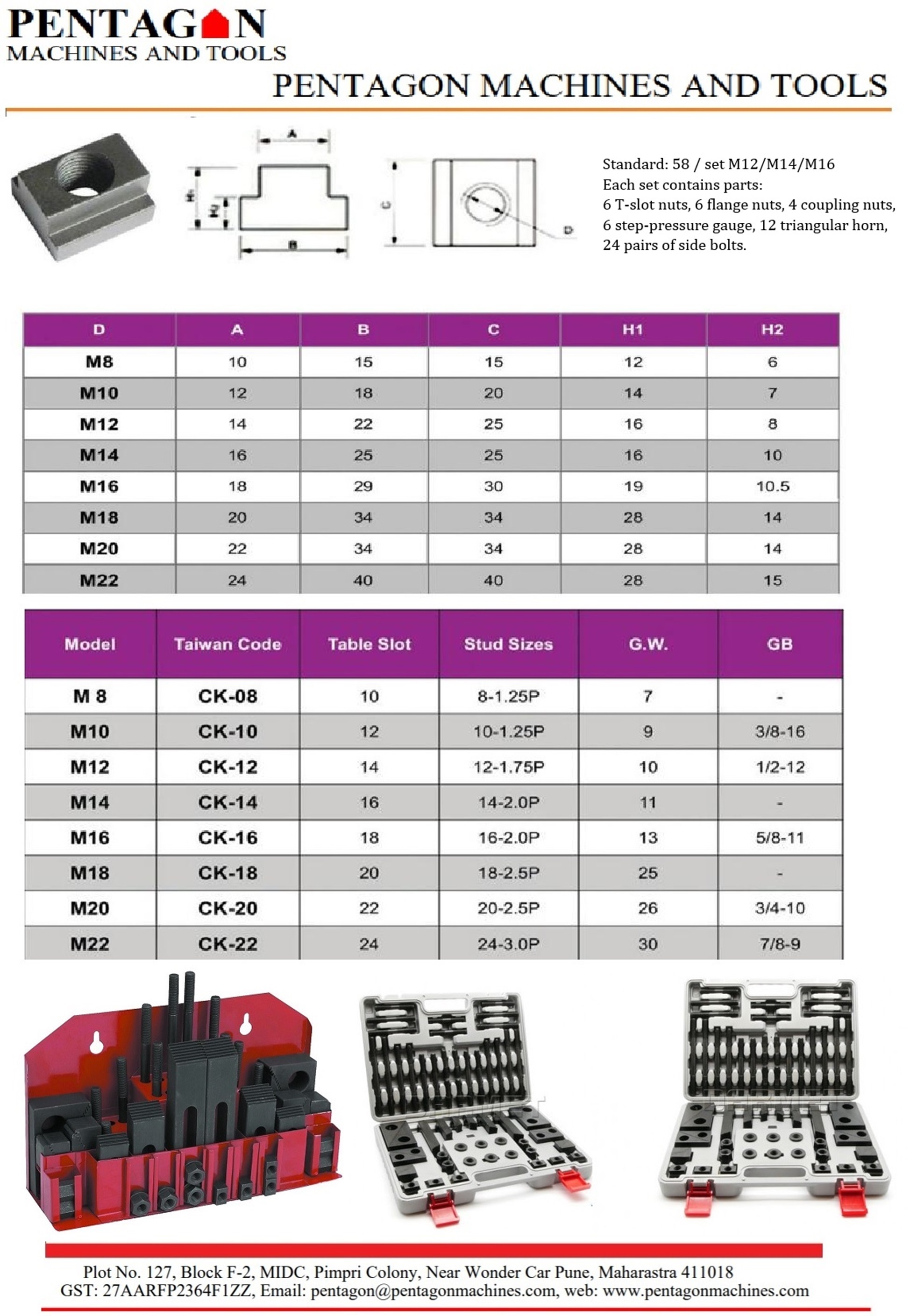

CLAMPING KIT M16 type 58 Pcs

CLAMPING KIT M16 type 58 Pcs Specification

- Model

- M16 58 pcs assortment

- General Use

- Industrial clamping and fixturing for machine tables

- Weight (kg)

- Approx. 25-35 kg (depending on supplier) Kilograms (kg)

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Table Size

- Compatible with standard machine tables (refer to slot size)

- Floor Space

- Compact kit; fits standard tool cabinet

- Feature

- Corrosion-resistant, durable, versatile for mounting

- Packaging Type

- Kit box/case included

- Application

- Workpiece securing, fixturing on machine tables

- Surface Finish

- Black oxide/Black painted as per supplied image

- Kit Pieces

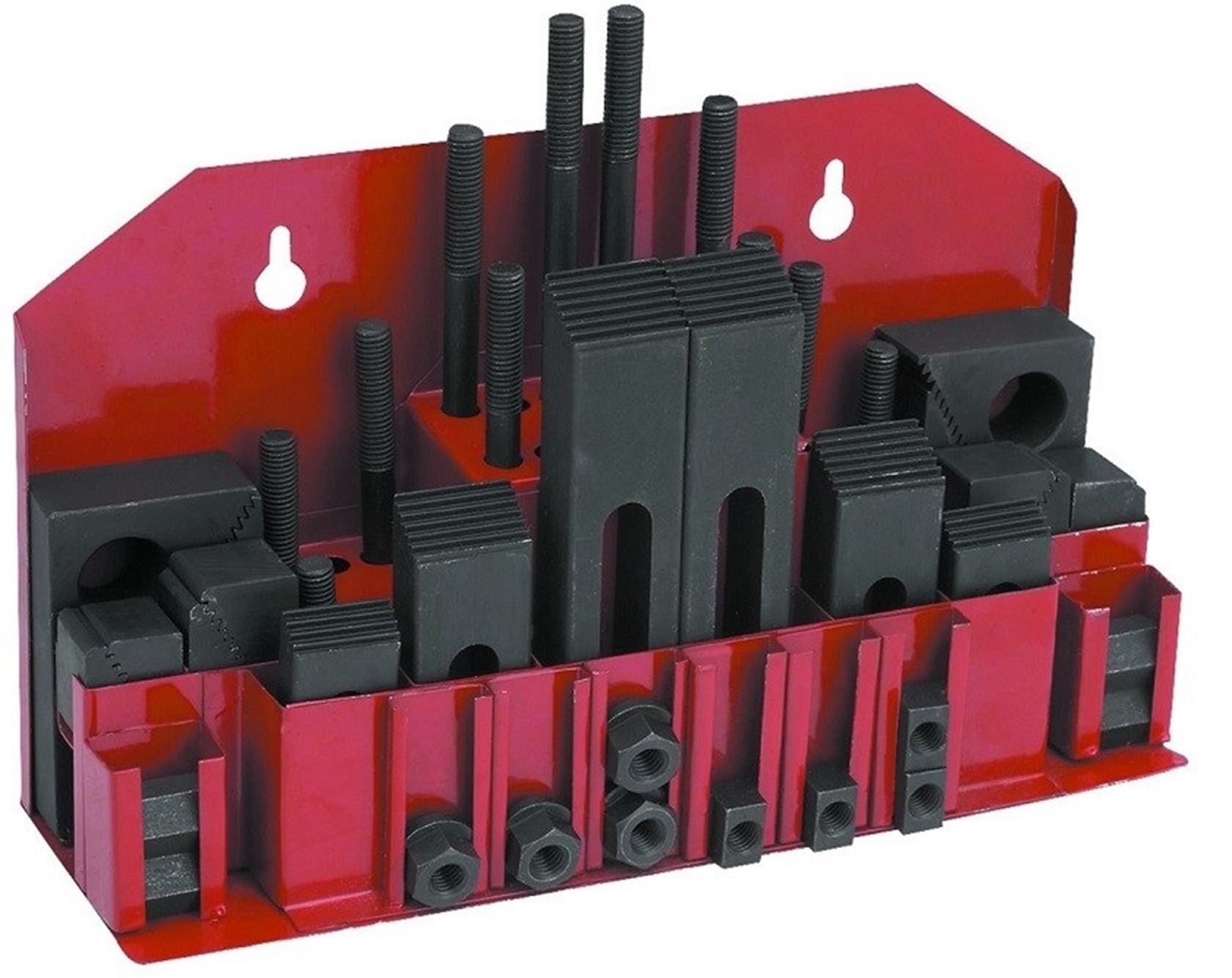

- 58 pieces including T-nuts, studs, flange nuts, step blocks, step clamps, coupling nuts, and hold-downs

- Compatibility

- Fits M16 T-slots commonly found on milling, drilling, and machining tables

- Storage

- Supplied in metal/plastic case for organized storage

- Stud Length Range

- Variety of lengths suitable for work holding

- Clamping Bolt Size

- M16

CLAMPING KIT M16 type 58 Pcs Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About CLAMPING KIT M16 type 58 Pcs

Clamping Kit Set Size M16 type58Pcs

Each set contains parts:

6 T-slot nuts,

6 flange nuts,

4 coupling nuts,

6 step-pressure gauge,

12 triangular horn,

24 pairs of side bolts

Key Features:

-

Set Size: 58 pieces complete set

-

Thread Size: M16

-

Material: High-quality hardened steel for long life and durability

-

Application: Suitable for T-slotted worktables (commonly fits 16 mm slots)

-

Includes: Step blocks, T-nuts, flange nuts, coupling nuts, studs, and clamps

-

Storage: Comes in a sturdy metal/ABS case or wall-mountable rack for easy organization

-

Usage: Ideal for milling, drilling, shaping, and CNC applications

Benefits:

-

Provides strong and secure workholding

-

Wide range of clamping options in a single kit

-

Quick setup and easy organization

-

Essential accessory for precision machining

Versatility Across Machine Tables

The CLAMPING KIT M16 is engineered for universal compatibility with standard M16 T-slots found on most milling, drilling, and machining tables. The kits variety of stud lengths and assorted components enable precise adjustment, making it suitable for securing diverse workpieces in a range of industrial setups.

Durable, Corrosion-Resistant Components

All 58 pieces in the kit are crafted from mild steel and finished with a black oxide or painted coating, offering robust resistance to corrosion and wear. This ensures dependable performance and longevity, even in demanding industrial environments.

Organized Storage for Efficiency

Convenience and accessibility are prioritized with a supplied kit box or case, crafted from metal or plastic. The compact storage system keeps components orderly, streamlining workflow and reducing setup time for operators.

FAQs of CLAMPING KIT M16 type 58 Pcs:

Q: How is the CLAMPING KIT M16 type used in industrial machining applications?

A: This kit is designed for securing workpieces and fixturing onto machine tables during milling, drilling, or similar operations. Simply select the appropriate componentssuch as T-nuts, studs, and clampsand assemble them to clamp the workpiece securely to the M16 T-slot table.Q: What components are included in the CLAMPING KIT M16 type 58 Pcs assortment?

A: The kit contains 58 pieces, including T-nuts, studs with varied lengths, flange nuts, step blocks, step clamps, coupling nuts, and hold-downs, all designed to facilitate versatile clamping setups.Q: When should I use a clamping kit with M16 bolts and T-slot compatibility?

A: Use this kit whenever precise and stable workpiece holding is required on machine tables equipped with M16 T-slots, whether for conventional or CNC machining tasks. It is especially useful for fixturing and securing parts during complex operations.Q: Where can the CLAMPING KIT M16 type be applied?

A: It is suitable for use in industrial settings such as machining shops, manufacturing floors, and workshops that employ standard milling, drilling, or CNC tables featuring M16 T-slot grooves.Q: What is the process for setting up the kit components on a machine table?

A: Begin by selecting the necessary studs, T-nuts, and clamps based on workpiece dimensions. Position the workpiece, insert T-nuts into the T-slot, attach studs and clamps, then tighten flange or coupling nuts to achieve secure fixturing.Q: What are the benefits of using this kit for work holding?

A: The kit offers versatility, durability, and efficiency. Its corrosion-resistant finish ensures long life, while organized storage enhances operational convenience. The variety of components enables quick, reliable setup for different workpieces and tool arrangements.Q: Is the CLAMPING KIT M16 suitable for both CNC and manual machines?

A: Yes, the kit is compatible with both CNC and conventional machine tables due to its standard sizing and manual operation, making it universally applicable in most industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

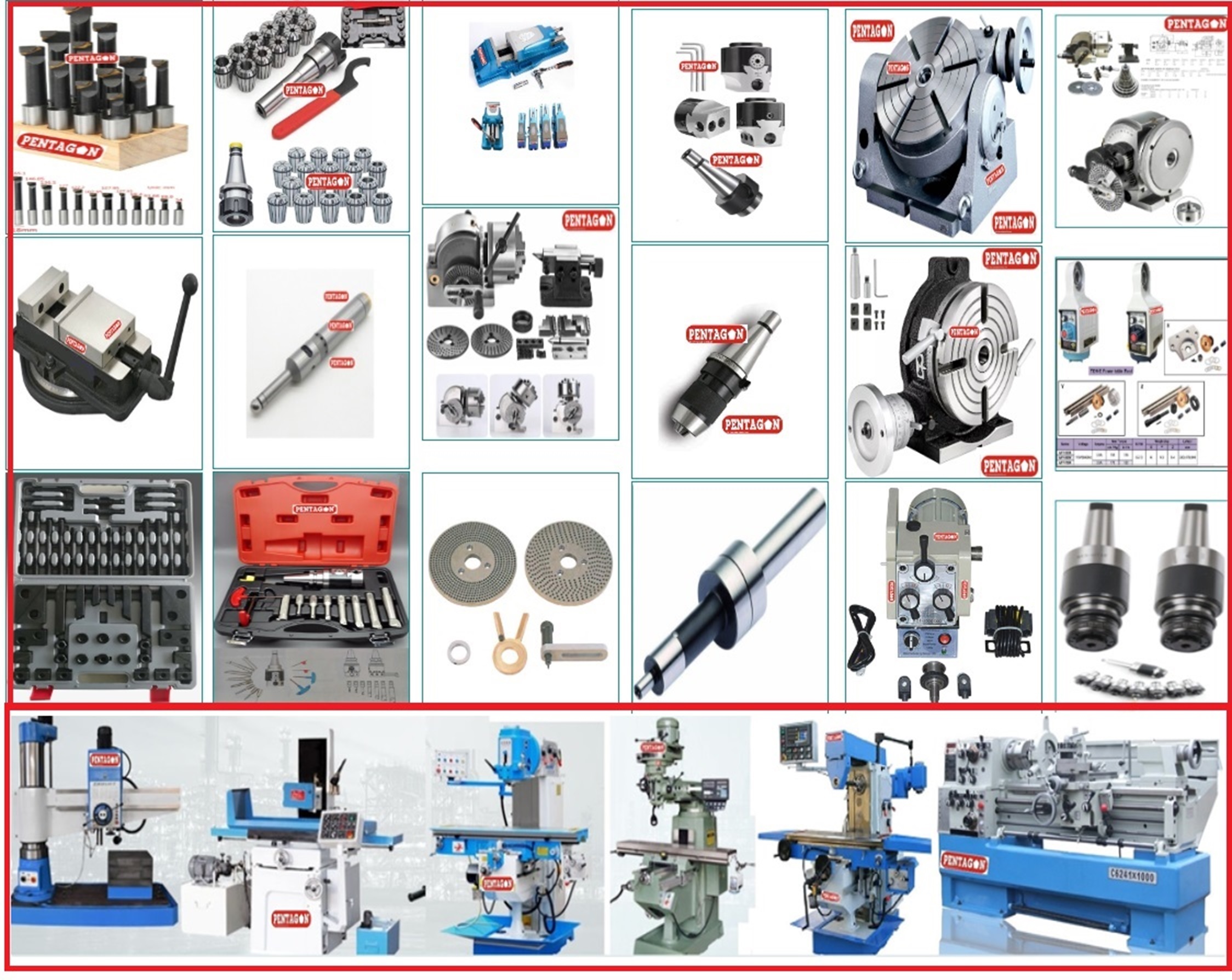

More Products in Machine Accessories Category

Delos brand DRO Set Along With 2 Axis DRO Display and Linear Scale

Price 17900 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Multi Color

Automatic : Yes

Product Type : Delos brand DRO Set Along With 2 Axis DRO Display and Linear Scale

Material : Other, Aluminum Alloy (scale), ABS/Metal (display unit)

Collect Set 10 Pcs ER40 Type With ISO40-NT40

Price 5700 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Silver

Automatic : No

Product Type : Collect Set 10 Pcs ER40 Type With ISO40NT40

Material : Stainless Steel

Quick Change Tap Collet Sizes from M6 to M30 GT24

Minimum Order Quantity : 10 Pieces

Color : Black

Automatic : No

Product Type : Quick Change Tap Collet Sizes from M6 to M30 GT24

Material : Stainless Steel

Micro Borning Head Model F-18 With ISO40 Shank and Alley Keys

Price 6200 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Silver

Automatic : No

Product Type : Micro Borning Head Model F18 With ISO40 Shank and Alley Keys

Material : Stainless Steel

|

PENTAGON MACHINES AND TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |