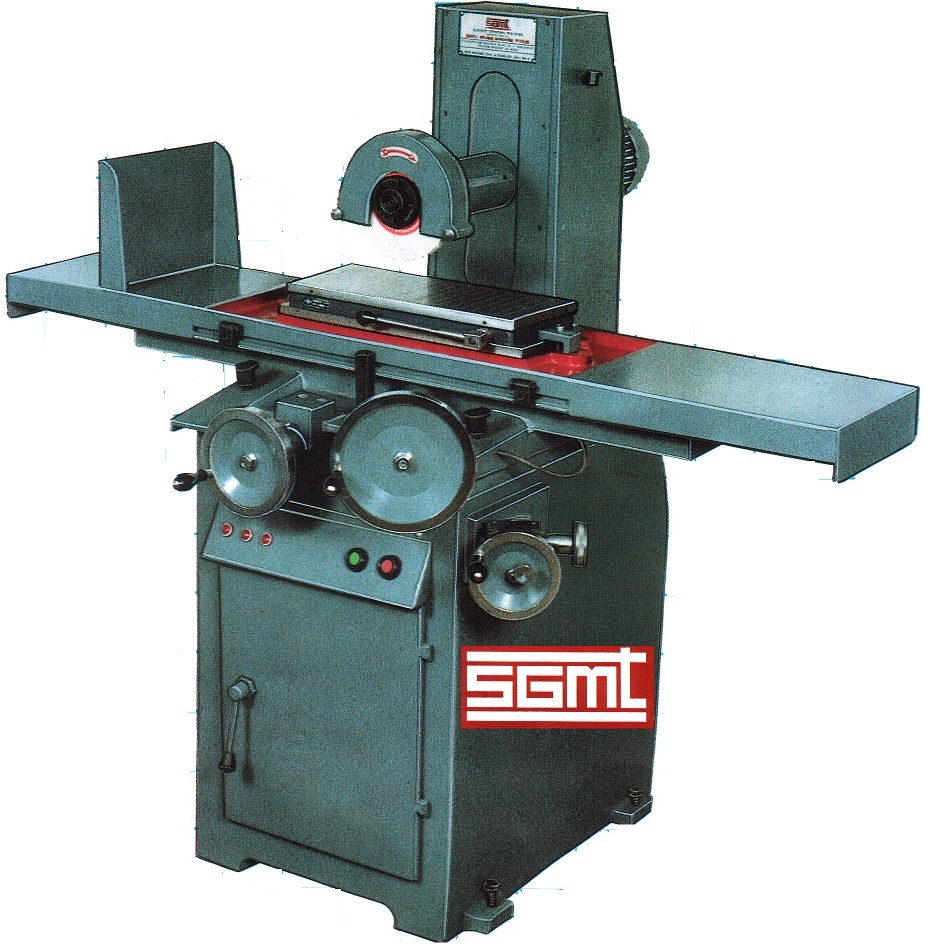

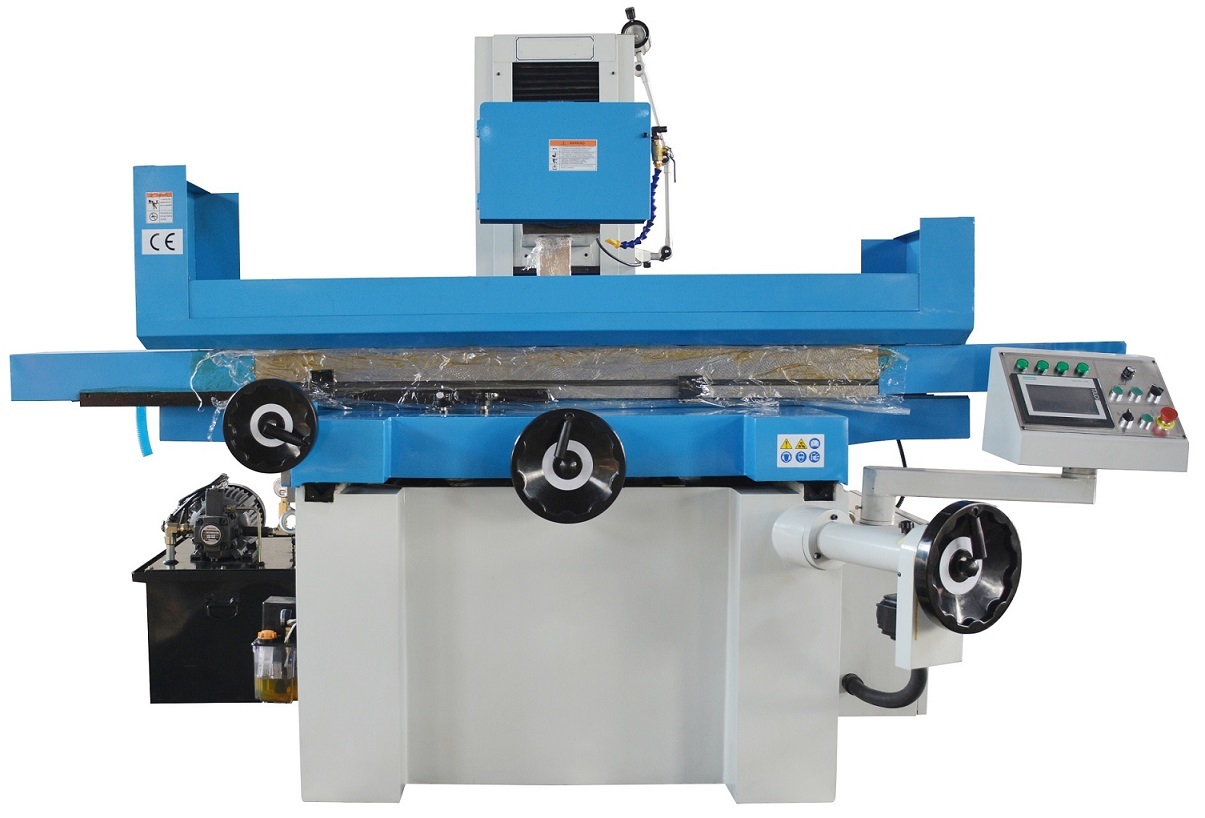

surface grinder

surface grinder Specification

- Product Type

- Hydraulic

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Hydraulic

- Voltage

- 415 Volt (v)

- Weight (kg)

- 1200 Kilograms (kg)

surface grinder Trade Information

- Minimum Order Quantity

- 1 Set

- Main Domestic Market

- All India

About surface grinder

Features Included

1. The machine has reasonable structure, good rigidity, beautiful appearance, convenient operation

2. Former after skidway through careful scraping flower, not only slide smoothly, and wear-resisting, maintain good accuracy, flexible and convenient operation

3. The spindle adopts super precision ball bearing P4, after strict selection after the pre pressure measurement, assembled in the greenhouse, and with the labyrinth design completely waterproof, In order to ensure the service life of the bearing and the grinding surface roughness

4. No vibration, low noise motor spindle

5. According to the needs of users with a permanent or electromagnetic chuck

Std Accessories Included

1. Coolant Tank &lamp; Equipment

2. Permanent Magnetic Chuck 8

3. Wheel Dresser Base

4. Flange & Wheel Extractor

5. Grinding Wheel

6. Balancing Stand with Shaft

7. Power Pack with Motor

8. Hydraulic Cylinder

9. Service Tools

Tech Details :

Model : HSG 1020-S

Table working Area : 500x250 mm

Longitudinal Table Travel : 520 MM

Cross Feed Table Travel : 250 MM

Distance Spindle centre to Table : 300 MM

Magnetic chuck recommended : Permanent magnet Chuck 200x500

T Slot : 10 MM

Longitudinal table speed : 5-15 MM/MIN

Cross feed on hand wheel : 5 1REV/MM

Cross feed on hand wheel : 0.05 1GRA/MM

Auto cross feed per stroke : OPTIONAL

Table guideways : V & FLATWAYS

Wheel dimension(dia x width x bore) : (200x13x31.75) MM

Spindle speed : 2800 RPM

Vertical feed on hand wheel : 0.01 MM/GRA

Micro Down feed : 0.002 MM/GRA

Spindle motor : 0.75 KW

Vertical motor : OPTIONAL

Hydraulic motor : 1.5 KW

Cross feed motor : OPTIONAL

Coolant motor : OPTIONAL

Lubricant motor : OPTIONAL

Machine height : 1600 MM

Floor space : 2400X1600 MM

Net weight Approx : 900-1000 KGS

Powerful, Consistent Grinding Solutions

Engineered for industrial performance, this surface grinder uses a PLC-controlled automatic system, guaranteeing precision across various metalworking tasks. Its hydraulic drive further enhances reliability, making it a valuable addition to any manufacturing lineup. With a weight of 1200 kg, the machine delivers stability, ensuring uniform surface finishes.

Versatile Distribution Across India

This surface grinder is accessible through an extensive network of distributors, importers, manufacturers, suppliers, and wholesalers throughout India. Whether you require bulk supply or individual machines, reliable sourcing and support services are readily available. Customers benefit from knowledgeable industry partners who understand diverse operational needs.

FAQs of surface grinder:

Q: How does the PLC control system improve the operation of the surface grinder?

A: The PLC control system automates the grinding process, allowing for precise adjustments and consistent performance. With programmable settings, operators can achieve accurate, repeatable results while minimizing manual intervention.Q: What materials can be processed with this hydraulic surface grinder?

A: This surface grinder is primarily designed for metals and is suitable for machining steel, cast iron, and other alloys. Its robust build and hydraulic drive ensure it can handle a wide range of workpiece sizes and types efficiently.Q: When is it beneficial to use an automatic, non-computerized surface grinder?

A: An automatic, non-computerized grinder is ideal when you seek reliable automation without the complexity of computer integration. It suits environments where ease of maintenance and straightforward operation are priorities, especially for repetitive industrial tasks.Q: Where can I purchase or source this surface grinder in India?

A: You can obtain this model from authorized distributors, manufacturers, importers, producers, suppliers, traders, and wholesalers across India. Many industry participants provide purchase, installation, and support services tailored to your business needs.Q: What is the primary process this surface grinder is used for?

A: This machine specializes in surface grinding, a finishing process to achieve flat, smooth surfaces on metal components. It is crucial in tool rooms, fabrication shops, and production facilities requiring high-precision finishes.Q: How can users benefit from the hydraulic drive feature in this grinder?

A: The hydraulic drive ensures a steady, controlled movement during operation, leading to smoother finishes and extended machine life. It also reduces vibration and wear, which enhances both performance and durability.Q: What safety features should operators be aware of when using this equipment?

A: Operators should follow all standard safety precautions, including using appropriate guards and wearing protective gear. The machines robust construction helps reduce operational hazards, but regular maintenance and adherence to operational guidelines are essential for safe use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Tools Category

PENTAGON Keyless Drill Chuck Model PKLDCR812M

Price 4700 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Threaded Mount

Control System : Other, Manual Adjustment

Automatic Grade : Manual

Color : Black

DELOS BRAND DRO Set along with 2 Axis DRO Display and Linear Scale Resolution 0.005 mm

Price 23400 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Electronic/Manual

Control System : Other, Microprocessor Based

Automatic Grade : SemiAutomatic

Color : Other, Grey/Black

DELOS BRAND DRO Set along with 2 Axis DRO Display and Linear Scale Resolution 0.001 mm

Price 26700 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Linear Encoder (Optical Grating Scale)

Control System : Other, MicroprocessorBased DRO Display

Automatic Grade : SemiAutomatic

Color : Other, Black (Display), Silver (Scale)

DRO and linear scale

Drive Type : Other, Electronic

Control System : Other, Microprocessorbased digital control

Automatic Grade : SemiAutomatic

Color : Other, Gray/Black

|

PENTAGON MACHINES AND TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |