सबसे लोकप्रिय उत्पाद

Specification

- प्रॉडक्ट टाइप

- सीएनसी या नहीं

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- फ़ीचर

- वारंटी

- 1 year

Trade Information

- Minimum Order Quantity

- 1 Set

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

About

DescriptioN

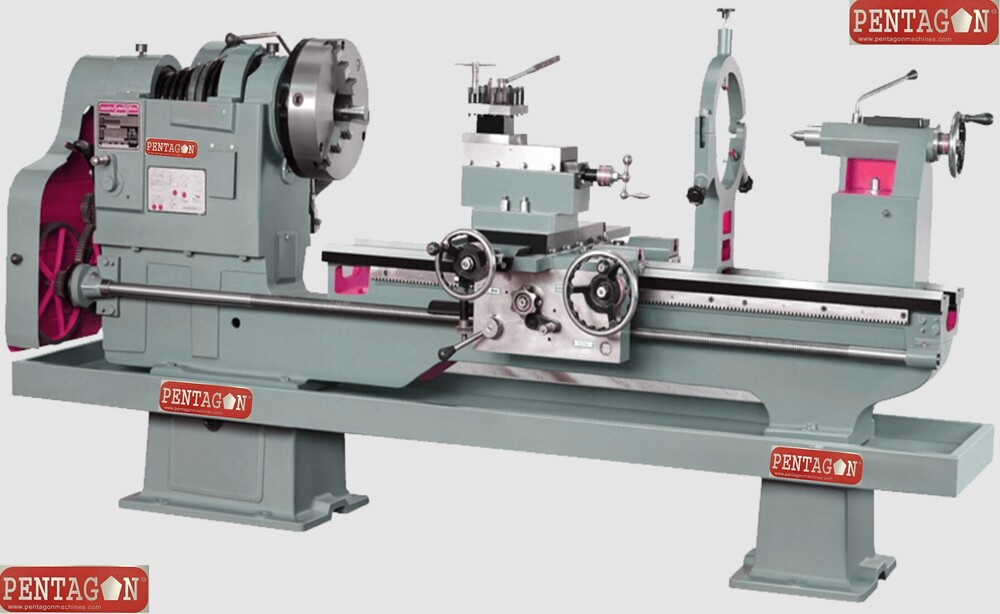

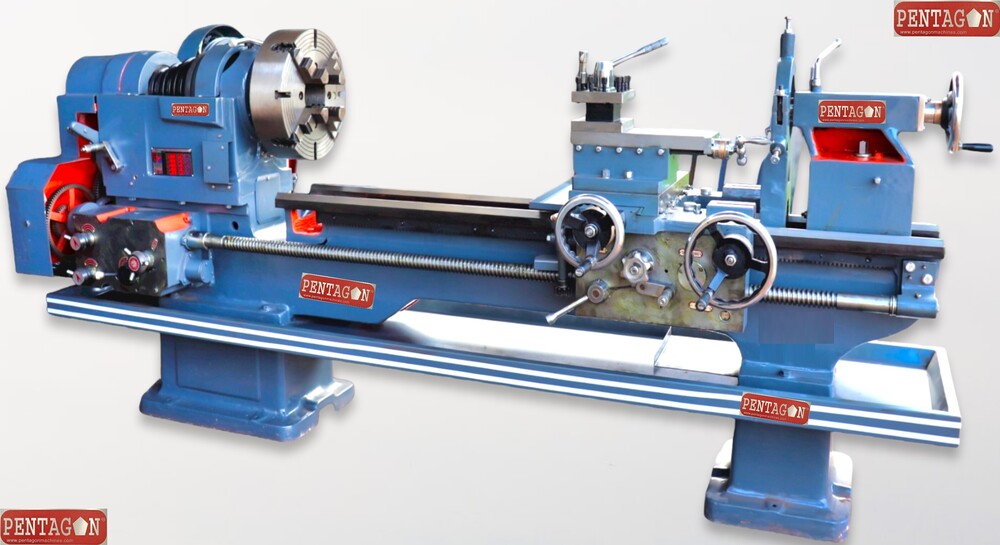

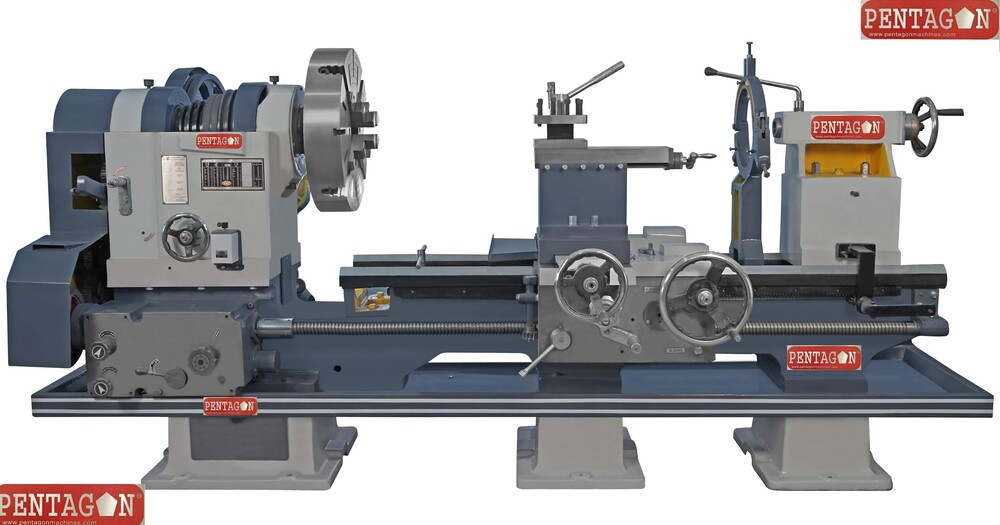

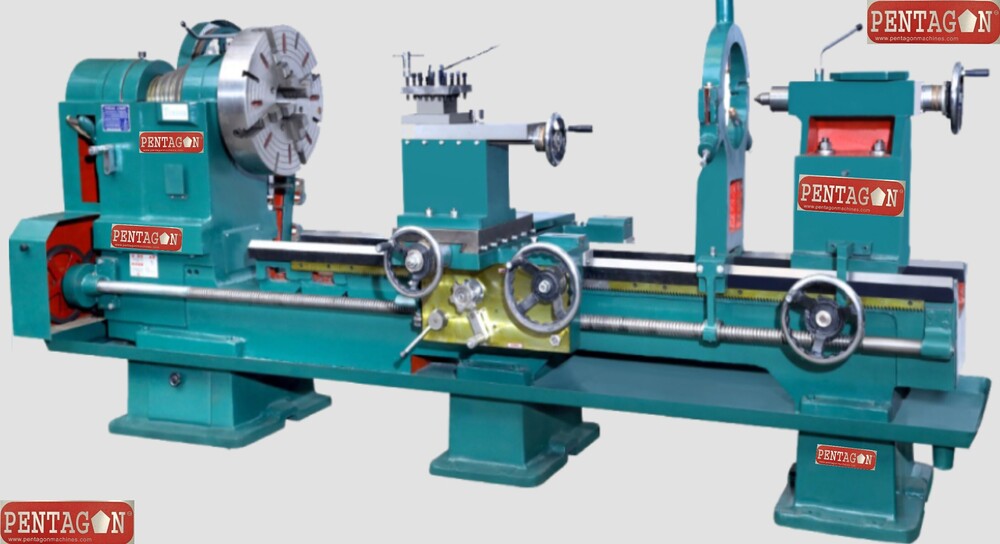

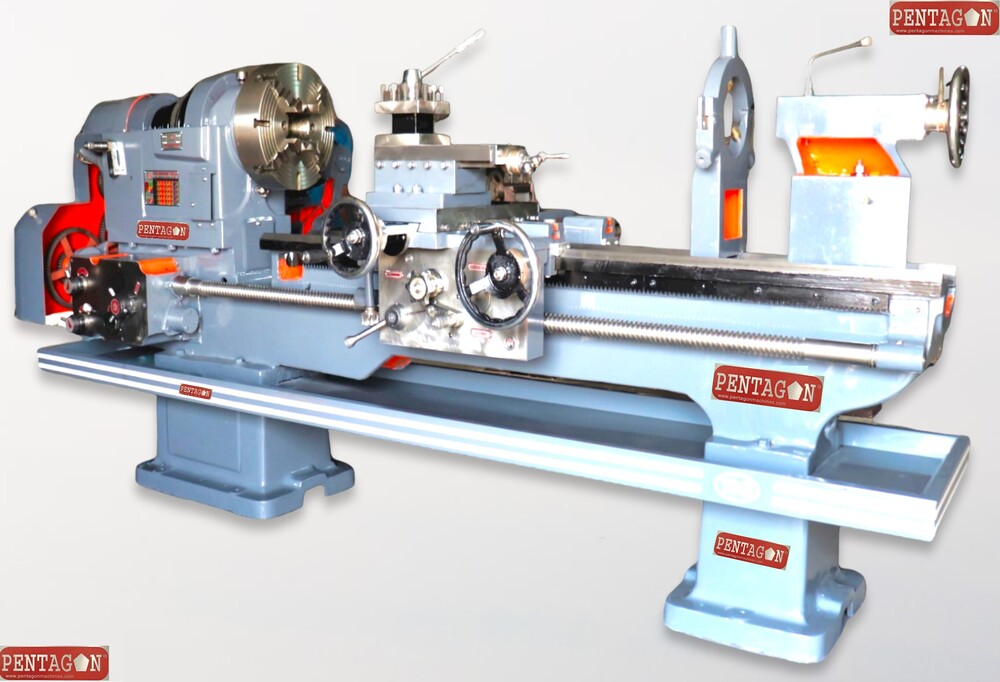

PENTAGON Brand Belt Driven Heavy Duty Lathe Machine Model PHDS 21307 bed length with center height 300 mm bed width 325 mm and Spindle bore 80 mm along with all standard accessories

Features Included

1 Flame Hardened bed ways

2 Latest Design Head Stock and spindle is made of alloy steel precision grinding

3 All rotating parts are balanced

4 HighGrade Cast Iron Construction Ensures rigidity and vibration damping

5 Powerful Main Spindle Motor Usually 375 HP

6 Tailstock Heavyduty manually or hydraulically operated

Standard Accessories

1 Chuck Plate

2 Change Gear Set of inch and mm

3 Dead Center

4 Center Adapter

5 Motor Pulley

6 Tool Post Key

7 Chip Tray

Optional Accessories

1 Coolant Pump with fitting

2 Machine lamp with fitting

3 Norton Gear box with fitting

4 Rear Safety Guard

5 Extra face plate

6 Quick Change Tool Post

7 Electric Motor 35 HP 3 phase

8 3 Jaw True chuck size

9 4 Jaw Dog chuck size

10 DRO set two axis with linear scale of suitable size fitted

Advantage

Vbelt systems are relatively inexpensive to manufacture and maintain compared to geardriven systems

The Vbelt can absorb shock loads and vibrations better than rigid gear systems protecting the machine and workpiece

Simple in construction easy to operate and less prone to mechanical failure

Produces less noise due to the beltdriven mechanism offering a smoother experience in the workshop

In case of overload the belt may slip which can prevent damage to the motor or spindleacting as a basic overload protection

Changing spindle speed is straightforward usually by shifting the belt between stepped pulleys

Fewer moving parts mean less frequent lubrication and adjustments are needed

Advanced Control with Human Machine Interface

Experience enhanced usability with the built-in Human Machine Interface, allowing operators to manage and monitor processes efficiently. The intuitive display streamlines adjustments and operations, making the machine suitable for various machining environments. This feature ensures accuracy and minimizes manual errors, contributing to consistent, high-quality results.

Eco Friendly and Reliable Performance

This lathe machine is designed to reduce energy consumption and environmental impact without compromising on heavy-duty performance. Its semi-automatic operation balances automation and manual control for flexible machining. With a 1-year warranty, users benefit from dependable support and minimized downtime, ensuring reliable productivity.

FAQs of Heavy Duty Lathe Machine:

Q: How does the Human Machine Interface enhance the operation of this lathe machine?

A: The Human Machine Interface (HMI) offers an intuitive way to control the machine, making it easier for operators to set parameters, monitor operations, and make real-time adjustments. This enhances efficiency, reduces the risk of human error, and streamlines complex tasks.Q: What are the key benefits of the semi-automatic grade in this machine?

A: Semi-automatic operation allows for a balance between manual precision and automated convenience. Operators have control over essential functions while benefiting from automation for repetitive processes, leading to improved productivity and flexibility in different machining applications.Q: When is routine maintenance recommended for this heavy duty lathe machine?

A: Routine maintenance is typically recommended at regular intervals, such as monthly inspections and lubrication, with thorough servicing suggested every six months. Refer to the manufacturers manual for specific guidelines to ensure optimal performance and warranty compliance.Q: Where can I purchase this heavy duty lathe machine in India?

A: This lathe machine is available through a wide network of distributors, importers, manufacturers, producers, suppliers, traders, and wholesalers throughout India. Contacting authorized sellers ensures original products and after-sales support.Q: What is the process for claiming warranty service?

A: To claim warranty within the one-year period, contact the point of purchase or the manufacturer directly. Provide the purchase invoice and machine serial number to initiate the service process. A support representative will guide you through repair or replacement procedures as required.Q: How is the machine considered ECO friendly?

A: The lathe is engineered with features that reduce energy consumption and minimize emissions during operation, aligning with environmental standards without compromising performance. This makes it suitable for businesses aiming to improve sustainability.Q: What types of jobs and industries can benefit from using this lathe machine?

A: Industries such as automotive, fabrication, metalworking, and general manufacturing can benefit from this machines robust build and versatile performance. Its ideal for applications requiring precision turning, prototyping, and large-volume production.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in LATHE मशीन Category

खराद मशीन

स्वचालित ग्रेड : ,

मटेरियल : Cast Iron

प्रॉडक्ट टाइप : ,

कंट्रोल सिस्टम : ,

वोल्टेज : 415 V

मूल्य की इकाई : नंबर

ऑल गियर्ड हाई स्पीड हाई प्रिसिजन लेथ मशीन

स्वचालित ग्रेड : ऑटोमेटिक

मटेरियल : हल्का स्टील

प्रॉडक्ट टाइप : लेथ मशीन, अन्य

कंट्रोल सिस्टम : PLC नियंत्रण

मूल्य की इकाई : टुकड़ा/टुकड़े

स्टेपर मोटर्स और पीएलसी आधारित नियंत्रक के साथ सीएलटी 100 सीएनसी लेथ ट्रेनर

स्वचालित ग्रेड : ,

मटेरियल : Mild Steel, Aluminum, Stainless Steel (structural and facing components)

प्रॉडक्ट टाइप : ,

कंट्रोल सिस्टम : ,

वोल्टेज : 230V AC, 50 Hz, Single Phase

|

PENTAGON MACHINES AND TOOLS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |